Contributed by:

ranger2000

Submitted: 25-07-2003

Introduction:

Introduction: Every

serious growing box needs cooling. Most of us use air

cooling because it is cheap and very effective. The

following steps are used to design a simple fan-cooled

box.

This method does not cover active cooling with

air conditioning systems or 'CoolTube' designs. It is

for grow chambers where the walls are approximately

equal to the light pattern, totally enclosed for airflow

control, and do not have large radiant heat into or out

of the box. Your mileage may vary some for these

reasons.

I also picked sane defaults for growing

conditions. The formulas

diverge if you get too far out

of plant growing range. You should be very safe if you

are within about 40 to 150 degrees F and 20% to 90%

humidity ranges (those are just guesses). Atmospheric

pressure was picked as sea level and doesn't really

affect anything until about 5,000 or 8,000 feet

depending on how accurate you want to get. If extreme

conditions apply to you, there may be other FAQ entries

with the entire full blown set of

pressure/temp/airflow/humidity parameters.

Design 1) Start at the

beginning and design this right! Before you ever buy or

cut anything for your new project, determine the highest

temp (in F) your intake air will ever be when lights

run. Get a thermometer and measure it to make sure you

have a good value. Call this

T(inlet)

2) Use these formulas to determine

difference in temp you can tolerate. 81F (27F) is about

the optimal for growing, 86F/30C on the higher end.

Tdiff = 81F - T(inlet) (English)

Tdiff = 27C

- T(inlet) (Metric)

3) Add up wattage for

all power in your box. Lights, pumps, heaters,

humidifier, radio, coffee pot, whatever. Add it all up

and call it Watts. This will make your number worst-case

and therefore a conservative value.

4)

Compute the absolute minimum fan power you will need

using the following formulas. This is the minimum fan

rating you must have to achieve your temperature goals.

You will have to increase fan power to compensate for

duct constrictions, small inlets, carbon scrubbers,

screens, or other items that block airflow.

CFM

= 3.16 x Watts / Tdiff (English)

CMH = 2.98 x Watts

/ Tdiff (Metric)

The formulas are almost

identical, due to the counteracting effects of

converting airflow from CFM to CMH, and converting temp

from Fahrenheit to Centigrade.

formulas can be found on this web

page: (This web site also lists the

above formula and uses a constant of 3.16 as shown

above)

5) If you have more than one fan,

they should be mounted side-by-side rather than inline

if you want to add their different CFM ratings.

For inline fans, use the lowest airflow rating

of all fans in the path. A fan on the inlet and a fan on

the exhaust of the box are considered inline fans. Fans

inside the box should not be counted for airflow but

must be included in wattage. A standard computer fan is

normally right around 30 CFM (50 CMH).

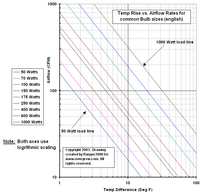

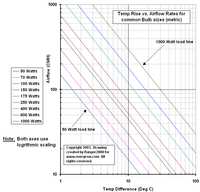

The two

lookup charts solve this equation for common lights.

Make sure you get the proper one (English or metric).

For those of you who are wondering if you did this

right, here are a few numbers in English units :

| Watts |

CFM |

Tdiff |

| 70 |

30 |

7.4 |

|

| 150 |

30 |

15.8 |

| 150 |

60 |

7.9 |

| 150 |

130 |

3.6 |

|

| 250 |

130 |

6.1 |

| 250 |

265 |

3.0 |

| 250 |

400 |

2.0 |

|

| 400 |

130 |

9.7 |

| 400 |

265 |

4.8 |

| 400 |

400 |

2.7 |

|

| 600 |

265 |

7.2 |

| 600 |

465 |

4.1 |

|

| 1000 |

30 |

105.3 |

| 1000 |

265 |

11.9 |

| 1000 |

465 |

6.8 |

Note: a 30cfm

computer fan is trying to cool a 1000w HID bulb, in the

3rd from the last row, as an extreme example

If

you are adding any carbon scrubbers or extensive

ductwork, this is where you add to the fan size to

account for air pressure losses. You have to move this

many CFM, or the numbers don't come out right. The

deciding factor for these items depends on your exact

configuration and is beyond this discussion.

6) When your box is built, buy a

thermometer and measure the air blowing out of the box

(temp probe or thermometer should be in the air stream

just after the fan, outside of the box enclosure) and

the temp of the air entering the box (again, from

outside the box perimeter). Make sure there is no direct

light shining on the thermometers to ruin the

measurement. DON'T MEASURE THE TEMP INSIDE THE BOX

YET!!!! It's best to do this with 2 thermometers or a

single thermometer with a remote probe. Cheap

thermometers don't work well because they aren't very

accurate. If you only have cheap thermometers, use the

same one for all measurements to avoid accuracy issues.

7) Subtract your measured inlet from

measured outlet temp. Compare to Tdiff from above. Is

your measured difference as good or better than your

estimated from step 2? If not, go find out why. Your

problems are probably:

A. Heat source you didn't

account for (the ballast?)

B. Your fan is overrated

C. You have blocked airflow

D. Your temperature

measurement was inaccurate

E. Air leaks into the box

(especially around the fan!) that ruin efficiency.

8) Once you get your measured temp

difference equal to step 2, measure temps inside the

box. Don't let the light shine right on the sensor, it

will give faulty readings!! Use a light shield made from

a tin can or something. If temps inside the box are

higher than your exhaust temp at a reasonable distance

from the bulb, you have air circulation problems inside

the box. Get some kind of fan to stir up the air in

there or look for airflow paths that allow air to travel

from inlet to exhaust without spending any time in the

box.

9) Always monitor the temperature

difference between inlet and outlet temps every time you

water the plants. If it varies much more than a degree

or two, find out why. I use digital indoor/outdoor

thermometer. It tracks high and low for both locations,

outdoor probe is on a long wire, $14 at Kmart. No part

of the thermometer is inside the box, just in the

measuring air blowing in and out from the outside.

Please note that conversion values have been

slightly rounded off to make this easy. Using the metric

and english formulas will yield slightly different

answers if compared. The difference should be less than

one percent and can be ignored.

You can use the

two load graphs attached if you prefer to do

calculations visually rather than using the formulas

listed above. Find the line for your light wattage and

ignore all others. Each axis is logarithmic, make sure

you count along each axis properly. The formulas listed

in step 4 were used to make the graphs.

Sidenotes: You can measure your

fan airflow very accurately if you use a standard

trouble light with a 60 or 100 watt bulb in it. These

are very good test loads for calibrating things.

Just put it in and work through the formulas using a

good thermometer to determine airflow. If you doubt the

accuracy of your bulb and are really anal about it, you

can calibrate the bulb against your electric meter over

several minutes. You could also stick in a different

brand of bulb at the same wattage and compare results. I

haven't tried this, but I would just trust the bulb

until proven wrong.

Testing and measuring

duct losses: Ducting losses are hard (to

measure) because they rely on knowing your duct material

coefficients. You

can measure the losses in the

duct after it is built and running, if that would help.

You could measure a test section to calibrate that

material, then extrapolate. Here's how:

Take a

known fan (or the fan you will be using) and blow it

into a plenum that has a heat source and some of your

sample duct mounted to it. To do this, you need a

trouble-light or other low wattage known source and a

cardboard box to put it in, then mount the fan on the

box and stick the duct on the other side.

Calibrate the box by measuring temps without the

ducting, then compute CFM. Add the duct, measure the new

temp, compute the new CFM. The difference is duct loss.

Basically, use temperature and wattage to measure

airflow and compute duct loss.

If you have an

existing room, just measure inlet and exhaust temps, add

up the watts, and then compute effective airflow. I just

did this for my box and it's pretty much dead on. I

think it varies by about +/- 0.2 DegF for 150 watts and

two computer fans.

Once you have the value for

your ducts, you can estimate loss by adding up the

length. We would have to come up with adjustment for

going around corners.

I once saw a Mech Eng.

book that had different shapes of pipe listed (Tee, 45

Deg bends, 4-way branches, Y-branches, etc) and then

gave an equivalent length of straight ducting they add

for flow resistance.