What is a suncircle? (circular light mover)

| Added by:

10k Last edited by:

10k Viewed: 438 times |

Rated by 5 users:

10.00/10 |

What is a suncircle?

Contributed by : Erliquin

Made by

American Hydroponics, it is a 360 degree rotating light

balancer. It will rotate a single lamp or lamps and even

of mixed wattage and type over a crop profile in

continuous fashion without flex getting tangled. The

advantage it gives is a more even profile coupled with

greater efficiency of the lights used. They come in

three colors and three styles.

Yellow.

Purple.

Green.

As said, they come in

three styles and they are the 1LRS (One Light Rotating

System), the 2LRS (Two Light Rotating System) and

finally the 3LRS (Three Light Rotating System). For the

sake of this document, the discussion will be on a

purple 3LRS.

Avoid the green model as it has a light weight

yet weak chassis and can break away from the ceiling

mount. I know this from experience. Chose the yellow or

purple models as they can truly take the weight of low

bays which means remote bays will be a cinch. I have

used the yellow 2LRS and yellow 3LRS as well as the

purple 3LRS with satisfaction. Although heavier to

handle, the solid construction makes all the difference.

It is vital that a suncircle has inherent structural

integrity as lamps and a suncircle crashing down onto a

crop below would be a disaster. The purple 3LRS is rated

at 9kg (20lb) per arm load bearing.

It is

equally important that it is mounted to a ceiling with

sufficient load bearing. Check the joist or frame with a

few chin-ups. If it can take that, then a suncircle will

be safe to mount. Always over engineer in the

construction of a grow room.

This document will

also outline how to wire a suncircle, what a suncircle

consists of as in components, their maintenance as well

as ceiling mounting.

If considering the purchase

of a suncircle, it will consist of the suncircle, a set

of bull arms with extention arms, including low bay

bracket mounts and cord with pulleys for the lamps. It

will be expected that you use flex from your HID systems

to set the suncircle up. That's easy as this document

will detail.

Note: The cord and pulleys that

come with a suncircle are ridiculous. Far safer and

easier to use chain with dog collar clips. You won't get

electrocuted as one should always wear rubber soled

shoes in a grow room. It is after all a plant workshop

and not a fun parlor.

Note: Suncircles do not

come with male and female plugs for your hats. You must

buy a pair of female and male plugs for each hat you

wish to use with your suncircle. I will discuss this

shortly.

Note: The extension arms that come with

the bull arms have not been employed as I like to keep

my light concentrated so the crop is full of solid bud.

The extension arms simply slot into the bull arms and

increase the over all arm stretch by double. Depending

on model, suncircle arms can come in box aluminum or box

galvanized steel. The ones shown in this document are

aluminum.

Photograph showing clearance of a 3LRS suncircle

on a ceiling grow room exhaust with bull arms pointing

down. If one has a low ceiling without ceiling exhaust

encumbrance, the bull arms can be positioned facing up,

giving extra height on the hats to garden below. In

either configuration of bull arm use, always make sure

you secure bull arms firmly with the screws provided in

the bull arm mounts.

Please note that

all styles of suncircle will have different mounting

plates so the holes on the plates will not correspond to

the ceiling mount alignment you might have from another

model. If so, then make a plate that will accommodate

varied styles by lining up the plate at the hydroponics

shop. This will give one the advantage of borrowing a

suncircle from the hydroponics shop of purchase, if and

when you have a problem with your suncircle for prompt

garden installation and bearing you have good will with

the hydroponics folks. You will note in this picture

that there's holes in this aluminum plate to accommodate

three styles of suncircle. So make the ceiling mount

with two plates. One set permanently to the ceiling that

holds the fasting bolts and the other you can take to

the shop for easy measurements.

In this picture,

the suncircle is fully wired and flex attached. Short of

being ceiling mounted, bull arms attached and connected

off to hats/ballasts and with the power on, it is fully

operational as can be seen in this photograph.

Please note, that the suncircle is actually

upside down, as the ceiling mounting plate is sitting on

a tiled floor -- so imagine that the tiled floor is a

ceiling. You can see the black cord that brings power to

the the suncircle motor. Note the three flex cords on

the junction box located near the ceiling mounting plate

for the HID ballasts and the three flex female plugged

lines from the other junction house for the hats.

A

closer look at the suncircle and again without the

attached bull arms. It's actually the other side of the

suncircle not seen in the first photograph. For the sake

of ease to photograph, the suncircle is again upside

down with the ceiling mounting plate resting on a

kitchen sink. Note the two junction houses, electric

motor, brush points, ceiling mount plate, bull arm

mounts with securing screws and flex for lamps and

ballasts which lead off from the two junction houses. I

will discuss these shortly.

A close look at a

junction house with junction housing plate removed. This

junction house is the one that takes the flex from the

ballasts. It is identical in wiring to the junction

house that takes the flex to the hats.

It is a

good idea to write in indelible pen at each flex entry

point what station it is. In the case of this 3LRS,

there's three stations per junction house. Not only will

this make it make it easier in the wiring of the

suncircle, it will ensure that the two junction houses

are identical in all regards.

Ensure that the

flex is held secure with the suncircle junction house

clamps as seen in the photograph. You want no wires

inside junction caps coming lose from flex being pulled

due to insecure hold as that can cause short circuit. I

will discuss wiring shortly.

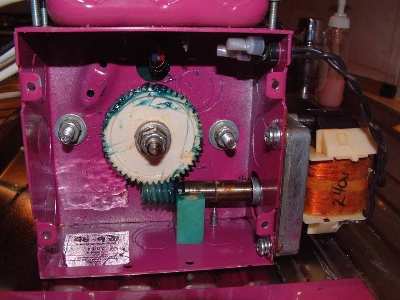

The suncircle

with ceiling mounting plate removed exposing the

interior mechanics in relation to the external electric

motor.

Note: Because a suncircle has to be taken

down so you can inspect and lubricate the inner

workings, you must set the suncircle up in your grow

with intention that it will come down in an ongoing

basis. So think carefully on how you will ceiling mount

it. It may seem silly to say, but do not for example,

set it so the nuts to the mounting bolts can only be

accessed from the crawl space of a roof. Always have the

nuts on the bolts facing downwards to the grow below.

A

closer view of the internal mechanics.

It's

simply a drive shaft from the motor to a central cog

which in turn rotates the central core. It is advisable

every twelve months to take the suncircle down and

remove the ceiling mounting plate and grease the drive

shaft and the central cog. This can be seen in the

photograph with an evident blue residue of fresh grease.

Ordinary automotive grease is sufficient.

Note:

When in operation, do not force the suncircle. Doing so

can cause misalignment of the drive shaft to the central

cog which will result in the suncircle not rotating.

In this suncircle shown, one garden rotation

happens every 4 minutes and 20 seconds, so a little

patience is needed if a hat happens to be in the way

when inspecting a plant.

A view of the

suncircle motor.

Note: It needs an oiling every

month and you can see the oil well on the side of the

motor. Sewing machine oil is sufficient. Just a few

drops is all that's needed.

A look at the

brushes of the suncircle. Note: Some people refer to

brushes as bushes. Simple to remove with a flat head

screwdriver from the brush points.

A closer look at

the brushes.

Being that the rectangular prism is

copper it will wear out before the central core will and

this is intentional in design so the suncircle has a

long working life. Brushes are cheap but a worn core

equals a dead suncircle. However, it is advisable to

inspect the brushes along with your once every twelve

months check. Give the brushes a light sanding on

contact end if dirty from carbon. This will ensure that

there's adequate contact so circuit is effected.

If ballasts are in working order as well as

lamps and you note lamps failing to charge or failing to

fully charge and your suncircle wiring is correct, it

may be poor contact with a brush.

When needing

to inspect a suncircle or taking down a suncircle, you

must switch off all HID's with allowance to five minutes

discharge time for the HID capacitors. That will not

only insure a sound working life of the capacitors, it

will prevent potential electrocution. Then pull the HID

plugs from the wall as well as the suncircle motor plug.

Now it is safe to inspect the brushes. A suncircle with

i.e. 3000w of HID is not a toy and it can deliver a

lethal electrocution. Treat all use of a suncircle with

care. If the brushes appear in working order, then you

will need to take down the suncircle and inspect the

junction houses for possible lose wires. If all appears

normal and you know for a fact that your ballasts and

lamps are in working order, you will have to take the

suncircle back to where you bought it for service. Only

a qualified electrician should service a suncircle.

Wiring Guide -- picture showing an open and

wired junction house with earth junction cap removed.

Once having purchased a suncircle, you have two

choices. You allow the shop to wire your suncircle or

you do it yourself if you have no problems with some

basic DIY sparky work (electrical work). Doing it

yourself brings several advantages.

* It can

save you some money by not shelling to a hydroponics

store technician.

* You can get on with your

project immediately.

* You will become familiar

with how the suncircle operates.

* You will be

confident to attend to minor trouble shooting yourself.

* You will be able to cut the flex to exact

lengths based on what lengths are needed in your grow

room -- a task not easy to do when in a hydroponics

shop. The less length in flex from suncircle to ballasts

and suncircle to hats the better, as there's loss to

resistance in circuit in excessive flex.

If you

do decide to wire it yourself, you must do so correctly.

One must ensure that all wiring to the two junction

houses is exact to both junction houses. Failure to do

so will cause a short circuit which could not only

damage the suncircle, it could damage the HID ballast

and lamp. A very costly mistake to make. Fortunately

correct wiring is a simple task of following exactly a

chosen color combination of the wires inside the

junction houses.

Now it would be pointless

showing each and every wiring step of colored wires in

sequence, as it would simply be a series of photographs

of confusing "electrical entrails". So a text worded

description is best.

The following example is

how I wired this suncircle. In this example, it is a

3LRS and in lesser armed suncircles, there's simply less

wiring to do. The only important issue, other than

ensuring all wiring to both junction houses is

identical, is that the earth (green wires) is all set to

the one junction cap. Green is always earth.

Note: All wiring is to be held by junction caps

of approved safety standard. The junction caps that came

with this suncircle were inferior and I replaced them

immediately with what you see, which meet ASA in

Australia. This is most important as wires coming lose

from junction caps when suncircle is in operation could

cause a disastrous short circuit.

When wiring,

strip back 7.5 cm (3 inches) of outer flex insulation

and 1.5cm (2/3 of an inch) of inner core insulation. It

should come with your HID kits.

Note: If in the

case of a 3LRS as this one is, you will need 14 junction

caps.

Lamp 1.

Blue wire to Black wire of

suncircle.

Brown wire to Red wire of suncircle.

Lamp 2.

Blue wire to White and Blue stripe

wire of suncircle.

Brown wire to White and Red

stripe wire of suncircle.

Lamp 3.

Blue wire

to Blue wire of suncircle.

Brown wire to White and

Blue stripe wire of suncircle.

All green wires

joined to one junction cap.

The above is

repeated again exactly in the second junction house.

You could chose any other combination of colored

wire to colored wire, as long as both junction houses

are identical in wiring and again at risk of repeating,

that all green wires are always to one junction cap.

It's also probable that the colors that I've spoken of

will vary, as they did in my experience on 2LRS and 3LRS

yellow models. No problem, just make sure both junction

houses are identical to the color code you chose.

Looking at the photograph provided, you can see

the green earth is four wires in total with the junction

cap taken off to demonstrate. The fourth green wire is

the suncircle earth as the three green wires are from

the three HID flex.

Aside how the

suncircle is ceiling mounted, it should also be center

of your grow footprint. The old 3,4,5 math will do that.

That is, 3 squared plus 4 squared equals 5 squared,

which will give you a right angle so you can footprint

section a square from a rectangular room. Then suspend a

plumb bob at central point and you will know the central

floor point if needed i.e. to square out where the

reflectors of your grow will go.

Equally

important is making sure that the suncircle is level in

mount. Simple tighten or loosen the bolt nuts on the

ceiling mount plate till level. You can if unsure,

inspect with a spirit level by laying it across the bull

arms. This will ensure that there's no strain placed on

the suncircle motor when system is in rotation.

Another view of the suncircle ceiling mounted

and now awaiting the hats to be attached. Use cup hooks

to tie off the ballast flex to ceiling and position the

hat flex on the bull arms.

As seen in the

photograph, it is a wise idea when attaching and wiring

your flex to the suncircle to use female plugs from the

suncircle and male plugs from the hats. This allows fast

removal and setup of your hats. Often times suncircles

on display in hydroponics shops will not have female and

male plugs set on suncircle to hats. That's perfectly

fine for a shop display, not very practical for growing

operation.

I will repeat stating this important

point. Always use female plugs from the suncircle and

male plugs from the hats or risk electrocution by errant

contact to active male points. Use common sense.

Equally important.

If using a mixed lamp

configuration of Metal Halide and High Pressure Sodium

and/or different wattages such as 400w and 1000w, always

mark clearly with an indelible pen on the female plugs

from the suncircle which are which. That way you will

avoid plugging in a hat to the wrong ballast.

Final picture of a marijuana crop with suncircle

and lamps in action.

|

| Last modified: 04:24 - Jul 12,

2002 |

| |