GrowFAQ:

How do I build my own Cool Tube?

| Added by:

snoofer Last edited by:

10k Viewed: 698 times |

Rated by 43 users:

8.13/10 |

Original Concept Credit: johnstone, NIMBY

Written by: Don'tTreadOnMe

Additional

info by: sanclem

Compiled & edited by:

Smokey D Dope

Configuration

This type of fixture

is very versatile. There are many different ways it can

be configured:

*hanging or mounted on a chamber

wall

*open-ended drawing air from the grow or ducted

to a separate intake

*passively or actively cooled

Tools Needed:

*Power drill with 1/8"

or 3/16" drill bit

*4.25" hole saw

*pop rivet

gun (optional)

*flat head and Phillips head screw

drivers

Materials:

Keep in mind that the full list of materials you

will need depends on the type of glass you get and the

configuration you're looking to build. Here's the

materials list with some pictures and approximate

pricing:

$3.99-- Glass, either 4" Pyrex tube

(approx. 12" long, 4 diameter) or "hurricane" lamp

glass ($3.99 at Hobby Lobby, is 11 3/4" long and 4 5/8")

$2.99-- 4" H/C venting starter collar

$4.50-- 5" to 4" venting pipe reducer (for use with

hurricane glass only)

$3.00-7.00-- High-temp foil

tape

$5.00-- Thermal pipe wrap (looks like woven

fiberglass tape with no adhesive)

$8.00-- 4"

aluminum "dryer" ducting (hanging configuration)

$2.00-- 1/2 wood screws (box wall mount only)

$3.00-- pop rivets or small sheet metal screws

4"

(dryer ducting and/or Pyrex tube only) and/or 5"

(hurricane glass only) hose clamps

"S" hooks (for

hanging)

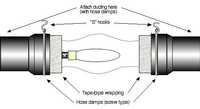

a. Hurricane glass tube

When working with the hurricane

glass "chimney," the irregular shape needs to be

overcome so that it can be attached it to a reducer

collar that will make up one end of the fixture. You may

attach a reducer collar to a single end if you want an

open ended design, or you can attach one to each end if

you will be running ducting to both intake and exhaust

ports.

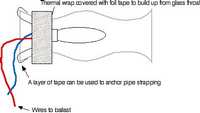

The graphics concentrate on

the exhaust end to which the bulb socket is also

anchored. On this end of the glass (at the narrow

"throat") numerous wraps of thermal pipe wrapping are

wound around the glass and secured with a couple of

wrappings of foil duct tape. The wrapping should build

up the throat to the same diameter as the opening in the

glass - where it snugly fits inside the larger end of

the reducer. The graphics concentrate on

the exhaust end to which the bulb socket is also

anchored. On this end of the glass (at the narrow

"throat") numerous wraps of thermal pipe wrapping are

wound around the glass and secured with a couple of

wrappings of foil duct tape. The wrapping should build

up the throat to the same diameter as the opening in the

glass - where it snugly fits inside the larger end of

the reducer.

This will allow us to use a 5" hose

clamp to secure the edge of the reducer collar to this

tape wrapped "cushion." (Note: you can use foil tape

alone for building this "cushion" but the thermal

wrapping makes for a neater seal, and is less

susceptible to heat. Also, if a hose clamp isn't

available, the reducer can be secured to the glass with

foil tape. This will allow us to use a 5" hose

clamp to secure the edge of the reducer collar to this

tape wrapped "cushion." (Note: you can use foil tape

alone for building this "cushion" but the thermal

wrapping makes for a neater seal, and is less

susceptible to heat. Also, if a hose clamp isn't

available, the reducer can be secured to the glass with

foil tape.

If you use a hose clamp, you will

need to make some 1" slits in the edge of the reducer

collar the glass fits in to allow the hose clamp to

compress it enough to hold the glass securely)

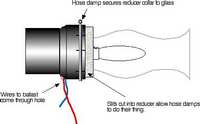

Mounting the socket inside the tube

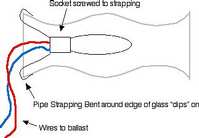

In the graphic, a length of pipe

strapping bent in a "U" shape is used to hold the socket

far enough inside the glass to place the bulb roughly in

the middle of the glass. This glass, $3.99 at Hobby

Lobby, is 11 3/4" long and 4 5/8" at each end. Notice

this glass is symmetrical. Don't try to use the

asymmetrical hurricane lamp "chimney's" available at

Lowe's or HD; they're too small and aren't shaped in a

way that permits good air flow. In the graphic, a length of pipe

strapping bent in a "U" shape is used to hold the socket

far enough inside the glass to place the bulb roughly in

the middle of the glass. This glass, $3.99 at Hobby

Lobby, is 11 3/4" long and 4 5/8" at each end. Notice

this glass is symmetrical. Don't try to use the

asymmetrical hurricane lamp "chimney's" available at

Lowe's or HD; they're too small and aren't shaped in a

way that permits good air flow.

The socket is

either screwed or pop riveted to the bottom of the pipe

strap "U." My light was made from a 150w HPS security

light which used a "medium" base socket; this socket has

two little screws in it that more or less lined up with

the holes in the strapping.

As for the mogul

base sockets used with bigger lamps, I don't know what

they have on the bottom of them so you may have to

improvise a solution for mounting them. The ends of the

strap are bent around to "clip" over the edge of the

glass and then secured with a couple of wrappings of

foil tape. If you'd like, a more permanent mount can be

had by drilling a couple of small holes in the tapered

throat of the reducer and attaching the ends of the

strap with a couple of pop rivets.

Running

the wires

The wires from the socket can be either

run through your 4" ducting which will attach to the

other end of the reducer or you can drill a hole in the

tapered part of the reducer to run the wire out of the

fixture to the ballast. The wires from the socket can be either

run through your 4" ducting which will attach to the

other end of the reducer or you can drill a hole in the

tapered part of the reducer to run the wire out of the

fixture to the ballast.

Here's how I actually

have it done in my box. There's no venting, it just

mounts to a 4.25" hole in the side of my flowering

chamber via a starter collar which fits snugly inside

the 4" side of the reducer collar. I've got them held

together with four pop rivets for a permanent

connection. The tabbed end of the starter collar fits

into the hole where the tabs are bent around the edge of

the hole and anchored with wood screw to the box wall.

(In my box, on the other side of this wall is my utility

room with a 4" 115cfm computer case fan sucking out the

back of it.)

One could just as easily connect

another reducer collar onto the other end of the glass

exactly as the first side was with "S" hooks for hanging

from above. This fixture could then have both intake and

exhaust from outside the box.

Originally this is

what I would have preferred to have, but as my flowering

chamber is only 2'Dx2'Wx3'H, the wall mount actually did

better for me.

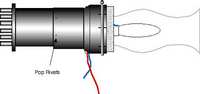

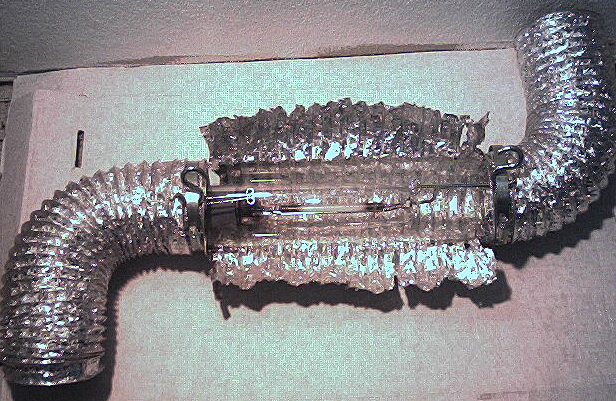

b. Pyrex baking tube

(NIMBY)

"Using a Pyrex (borosilicate glass) tube obtained from a

glass blowing supply house or using a "Bake a Round"

(eBay had a dozen for sale the last time I checked) one

utilizes either one or two (pictured) 4" starter collars

instead of the 5" to 4" reducer collars. They are 14"

long and 3.75" in diameter."

"I stretched the aluminum

ducting out and measured 16". I then snipped the metal

"ribs" and cut the ducting open. The glass tube will now

just drop into the long run of ducting. The electrial

wires run to the remote ballast through the intake part

of the duct (exhaust could also be used depending upon

the location of the ballast). I measured 2" from each

side of my original cut and snipped the metal ribs again

but this time didn't cut the aluminum foil. This allows

me to open the ducting up like a "wing"."

A couple of wraps of pipe

wrap sealed with foil tape on each end you want to put a

collar on should be used to keep from biting the metal

directly into glass with the hose clamp (pictured). The

socket is mounted inside the tube with pipe strapping

just as in the hurricane style fixture. It can either be

"clipped" and taped over the edge of the glass or

better, pop riveted to the inside of the starter collar.

Simply stick the glass inside the end of the

starter collar an inch or so past the bottom of the tabs

to measure how far in to drill two holes 180 degrees

apart, then use two pop rivets to attach the strapping

A note about pipe strapping: don't get

the thin wimpy stuff. Get the thicker heavy-duty

strapping. The heavy stuff is still relatively easy to

bend but holds it's shape better and will hold the bulb

and socket straight without sagging. At Home Depot they

even have some copper pipe strapping (also known as

pipe tape" or pipe hanger) that is quite stiff.

Ventilation Performance

There are

many different ventilation options available, since

standard household ducting is used in the construction

of the fixture. For those folks with bigger boxes or

rooms, ducting in and out, "inline" duct fans are

probably the best option.

For my little

NewGanjaBoy-style setup, using the Hurricane fixture as

part of the ventilation system of my box, a 115cfm

computer fan does the trick. As for actual performance

specs for different blowers/fans and light wattages, I'm

afraid you'll have to experiment. Here's mine just to

give an example:

Box:

-NewGanjaBoy-style three chambered box

-4 20w

flouros in the mother chamber

-150w security HPS in

the flowering chamber in original metal fixture with

holes drilled in the top

Ventilation before

Cool Tube installed:

-115cfm fan exhausting box

-4"x8" intake port in the bottom of the veg chamber

-Two 2' runs of 1.5" PVC pulling air through the

wall between veg and flowering chambers

-Two 1' runs

of 1.5" PVC pulling air from over the HPS fixture into

the utility room where it's exhausting out the back.

Ventilation after Cool Tube installed:

-Two PVC runs between flowering chamber and utility

room replaced with Hurricane Cool tube fixture

-ballast moved to utility room and housed in the

original security light casing

-everything else is

the same

Temps before Cool Tube mod:

Ambient temp: 80F

Flowering chamber 1 hour

after HPS fires up: 95F (in direct light)

Flowering

chamber 6-12 hours after HPS fires up: 100-105+F

(ouch!!)

Temps after Cool Tube Mod:

Ambient temp: 80F

Flowering chamber 1 hour

after HPS fires up: 85F (in direct light)

Flowering

chamber 6-12 hours after HPS fires up: 90F (in direct

light)

SAFETY NOTICE:

Please note

that the wire to the bulb base must be a high temp

fiberglass type, or the heat will eat up the wire and

cause a running short. The thermal tape is a fiberglass

electrical tape from most hardware stores. High temp

fiberglass wrapped wire is available at any hardware or

electrical store. It is imperative that you use it, as a

smoking ballast is a real bummer to relight.

|

| Last modified: 03:57 - Feb 21,

2003 |

| |

faq:1432 "How do I build my

own Cool

Tube?" | | |